From electrical repairs, lighting installation, and rewiring to new construction electrical installation and HVAC wiring, the variety of services we offer span many areas of electrical services for your home or business.

-

FREE Electrical Safety Check

-

1 Year Work Full Guarantee

-

XCel Energy Preferred

Quality workmanship by licensed and insured professionals

Our electricians do all your electrical repairs and other work personally. All our materials are of the highest quality and our quality workmanship offers you a safe and efficient electrical system.

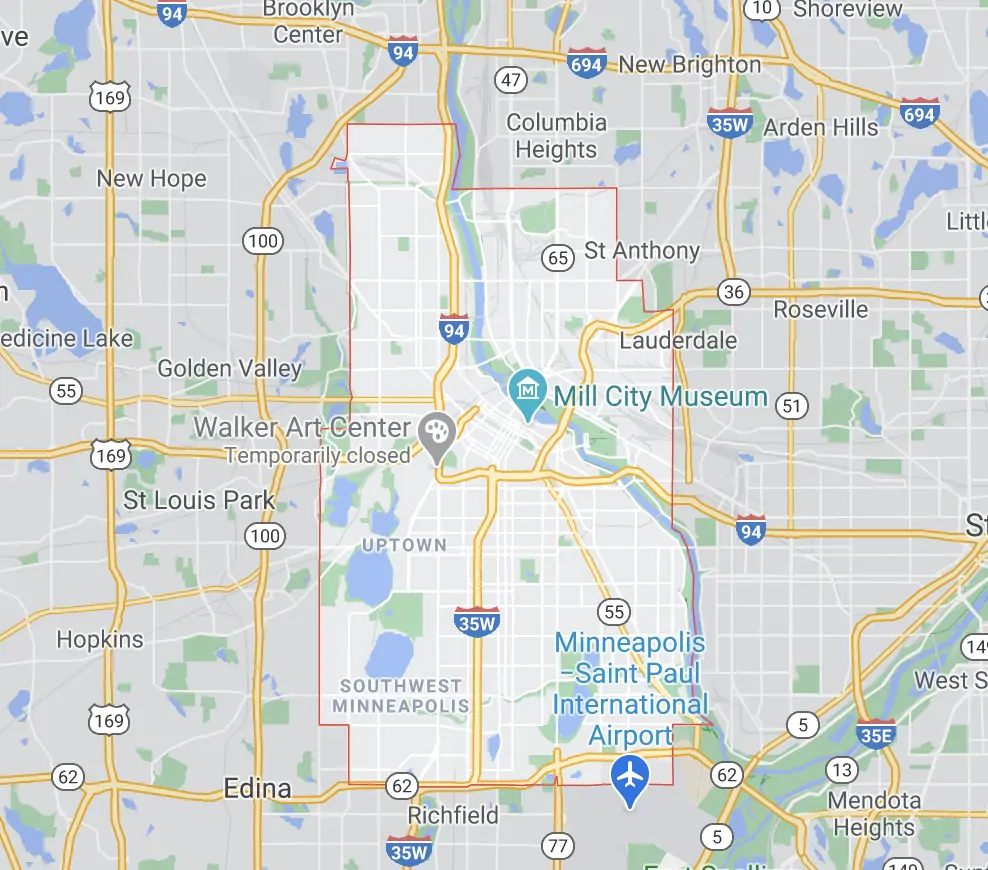

Let our electricians ensure you get your home or business electrical needs done right. Give us a call if you’d like to set up a free consultation and estimate at your location in Minneapolis!

Providing Minneapolis with Electrical Repairs

Our electrical contractors take every project seriously and strive to provide you with the highest level of quality work. We understand how serious electrical repairs are for you and your family. We take pride in the work we do and want your electrical repairs to be done right so you can depend on your lights or other components to function safely.

Local Professionals with a Proven Process

Step #1

Contact

Fill out a quick form to tell us a bit about how we can help. We’ll reach out to get started.

Step #2

Consultation

Set up an appointment with our estimator to develop the best plan for your electrical project.

Step #3

Proposal

We’ll provide you with a free estimate detailing the work to be done.

Step #4

Installation

Our fully licensed electricians will complete your installation or repair efficiently and answer any questions you may have.

Our Commitment to Service & Quality

We take pride in our Minnesota values of honesty, safety, respect, and quality workmanship. Installing only the best products, we stand by our work on every project.

Derek – Master Electrician

Electrical Safety Inspections and Wiring Services

Our electricians are highly trained and experienced to ensure your electrical panel, circuit breakers, wiring, and lighting, and more are safe and properly suited for your home. For electrical safety inspections and service that is second to none, call our Minneapolis electricians today!

We use only the best materials and quality workmanship when taking care of the electrical needs of our customers, and we make sure that our team of electricians are continuously educated in order to stay current with today’s electrical code standards and technology advances. We offer all this at a fair and highly competitive price.

Keep Your Home & Car Running The Way it Was Meant To Be

Recent Jobs and Reviews in Minneapolis, MN

Job Locations and Reviews

Responded to service call for noisy boiler pump serving the entire building. Diagnostic inspection revealed excessive vibration and noise from the circulator pump motor. Visual examination showed signs of corrosion on the expansion tank and connecting pipes, indicating potential system age and wear. Documented system condition with photographs for further assessment.

Responded to no-heat call for in-floor heating system in sunroom. Diagnostic testing revealed faulty wiring as the root cause. Completed repair of damaged wire, restoring proper functionality to the heating system. Inspected boiler and associated copper piping network, confirming all components now operating correctly.

Inspected property for reported radiator leak in bathroom ceiling. Discovered extensive water damage and ceiling deterioration. Determined actual cause was plumbing leak from toilet in unit above, not HVAC system. No boiler service was required.

Performed city-mandated safety inspection on furnace for code compliance and completed heat certification form. Conducted electrical testing with UEi EM720 meter and noted capacitor is weakening but still operational. Recommended future replacement of capacitor when convenient.

Responded to service call regarding boiler shutdown and reported electrical issues. Upon inspection, found the air valve was functioning properly with no active leaks, contrary to customer's initial concern. Visual inspection of plumbing system showed normal copper piping and brass valve assembly with no issues requiring intervention.

Responded to no heat complaint after recent maintenance. Diagnosed faulty gas valve using UEi Test Instruments EM720 meter which showed abnormal readings of 17.2. Temporary repair attempted but unsuccessful. Scheduled return visit with replacement part; customer to be available by 12:00.

Investigated reported chimney leak where previous furnace/AC installation included capping the chimney. Observed significant corrosion on the metal chimney pipe with visible rust bands. Interior inspection revealed potential exhaust leakage issues. Due to unsafe roof conditions, completed partial assessment and scheduled follow-up visit in approximately 2-3 weeks to complete roof inspection when conditions improve.

Responded to service call for leaking humidifier that customer had previously shut off. Inspection revealed water panel casing was slightly offset from proper position. Repositioned casing to ensure proper alignment with drain, resolving the leak issue.

Performed warranty replacement of defective air scrubber unit that was not illuminating or operating properly. Initial troubleshooting included power cycling the unit and testing functionality. Upon replacement, verified proper installation of new air scrubber and confirmed operational status.

Investigated ceiling leak reported by resident that occurs intermittently with radiator "clanking" sounds. Accessed the site using provided lockbox codes and inspected the existing ceiling opening. Enlarged the access hole to better examine plumbing infrastructure and identified water damage consistent with an intermittent supply line leak. Repaired the compromised pipe connection and documented the condition with photos showing the extent of ceiling damage and affected wall areas.

Responded to service call for non-functioning thermostats and lack of heat. Discovered tripped breaker affecting furnace operation. Restored system functionality and verified proper operation. Recommended customer consult with electrician regarding aged breaker box.

Diagnosed bedroom zone heating issue caused by low water pressure in boiler system. Identified noisy circulation pump and two non-functioning radiators. Restored system functionality by adding water to increase pressure to proper operating level.

Responded to service call for water leak under furnace. Diagnostic inspection revealed cracked condensation trap causing leakage. Visual inspection showed significant dust accumulation and corrosion on components. Customer advised that trap replacement is required. Will return in fall for scheduled preventative maintenance.

Performed scheduled boiler maintenance and tune-up in response to temperature discrepancy issue. Inspected burner elements which showed dust accumulation and cobwebs requiring cleaning. Checked system pressure/temperature gauges which confirmed customer-reported variance of 6-8 degrees between set point and actual temperature. Calibrated temperature controls to restore proper heating function.

Responded to complaint of excessive noise from condensate pump at furnace location. Diagnostic inspection revealed failing pump motor with significant mineral buildup and discoloration on internal components. Removed defective unit and installed new condensate pump, restoring proper operation and eliminating noise issue.

Responded to no heat call previously investigated by technician Andy. Performed comprehensive diagnostic testing of furnace with digital clamp meter, measuring voltage at 208.8V. Inspected gas valve, ignition system, and control board. System operated normally during testing with no error codes displayed. Recommended preventative replacement of gas valve if intermittent issue recurs, as burner ignition failure was previously observed. Completed scheduled Fall tune-up maintenance on standard furnace.

Performed scheduled heating maintenance on Utica Boilers unit. Identified faulty pressure gauge providing incorrect readings and replaced it. System now operating within normal parameters.

Completed fall preventative maintenance service on customer's standard furnace. Performed comprehensive inspection including electrical components and gas valve. Measured and verified proper system operation with diagnostic equipment, ensuring optimal performance for the heating season.

Responded to service call for non-functioning gas fireplace. Diagnosed failed gas valve preventing ignition. Observed significant corrosion and rust on valve assembly and surrounding components. Recommended complete valve replacement to restore proper operation.

Responded to service call for furnace failing to maintain set temperature. Diagnostic inspection revealed inducer motor with burnt plastic odor and blower motor showing oil residue. Presented customer with options for component replacement versus full system replacement; customer will consider both alternatives before proceeding.