From electrical repairs, lighting installation, and rewiring to new construction electrical installation and HVAC wiring, the variety of services we offer span many areas of electrical services for your home or business.

-

FREE Electrical Safety Check

-

1 Year Work Full Guarantee

-

XCel Energy Preferred

Quality workmanship by licensed and insured professionals

Our electricians do all your electrical repairs and other work personally. All our materials are of the highest quality and our quality workmanship offers you a safe and efficient electrical system.

Let our electricians ensure you get your home or business electrical needs done right. Give us a call if you’d like to set up a free consultation and estimate at your location in Minneapolis!

Providing Minneapolis with Electrical Repairs

Our electrical contractors take every project seriously and strive to provide you with the highest level of quality work. We understand how serious electrical repairs are for you and your family. We take pride in the work we do and want your electrical repairs to be done right so you can depend on your lights or other components to function safely.

Local Professionals with a Proven Process

Step #1

Contact

Fill out a quick form to tell us a bit about how we can help. We’ll reach out to get started.

Step #2

Consultation

Set up an appointment with our estimator to develop the best plan for your electrical project.

Step #3

Proposal

We’ll provide you with a free estimate detailing the work to be done.

Step #4

Installation

Our fully licensed electricians will complete your installation or repair efficiently and answer any questions you may have.

Our Commitment to Service & Quality

We take pride in our Minnesota values of honesty, safety, respect, and quality workmanship. Installing only the best products, we stand by our work on every project.

Derek – Master Electrician

Electrical Safety Inspections and Wiring Services

Our electricians are highly trained and experienced to ensure your electrical panel, circuit breakers, wiring, and lighting, and more are safe and properly suited for your home. For electrical safety inspections and service that is second to none, call our Minneapolis electricians today!

We use only the best materials and quality workmanship when taking care of the electrical needs of our customers, and we make sure that our team of electricians are continuously educated in order to stay current with today’s electrical code standards and technology advances. We offer all this at a fair and highly competitive price.

Keep Your Home & Car Running The Way it Was Meant To Be

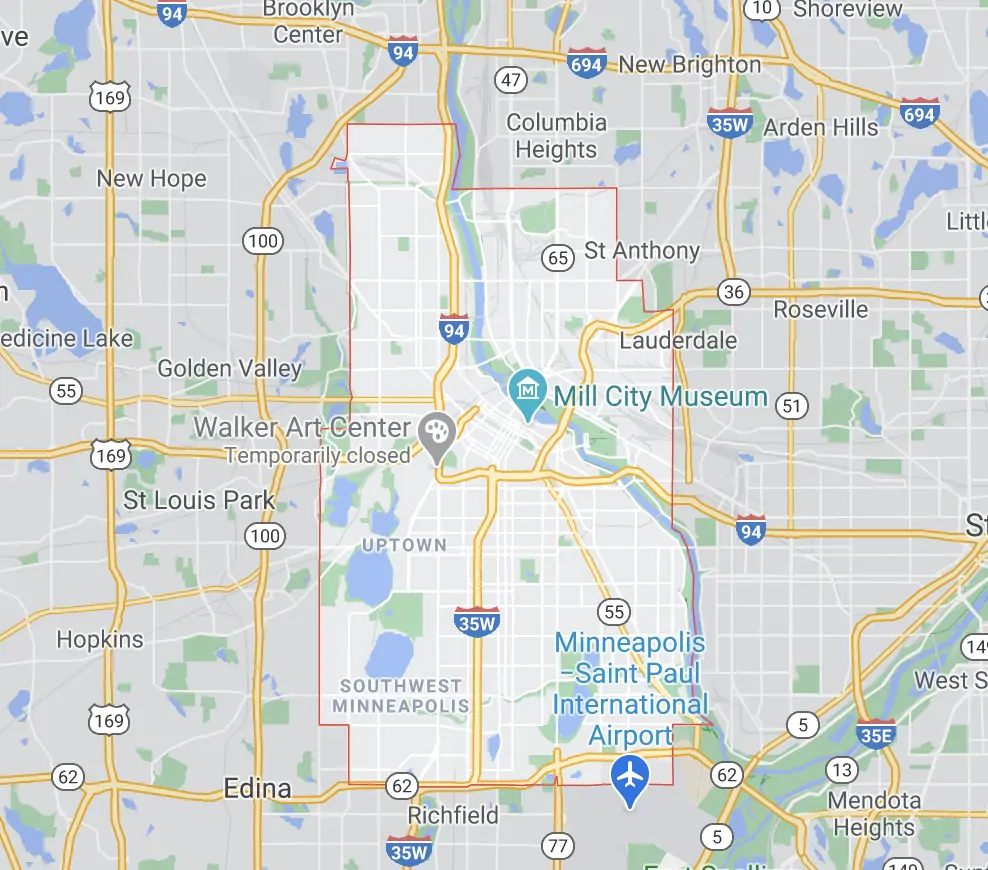

Recent Jobs and Reviews in Minneapolis, MN

Job Locations and Reviews

Provided comprehensive operational guidance to tenant on proper use of Triangle Tube boiler system. Explained maintenance indicators to monitor and demonstrated proper filling procedure. Conducted visual inspection of the equipment, confirming proper installation of boiler unit, water heater, and associated plumbing components.

Performed routine furnace maintenance and tune-up. Identified E9 error code caused by open high stage pressure switch. Inspected and verified proper operation of intake, exhaust, condensate drain system, and verified pressure switch readings to resolve the issue.

Responded to service request regarding boiler running hot. Upon inspection, identified faulty Taco zone board ZVC406-5 as the source of the issue. Removed existing damaged zone valve control system and installed new Taco zone board with proper wiring connections to all six zones, restoring normal operation of the boiler system.

Performed scheduled heating maintenance on system and identified a failed capacitor, which was replaced. Inspected humidifier system, cleaned evaporator pad assembly, and confirmed unit is functioning correctly for the heating season.

Performed scheduled Fall maintenance on customer's boiler system. Conducted visual inspection of burner assembly, confirming proper flame pattern with consistent blue coloration indicating complete combustion. Checked pipe insulation and valve functionality throughout the system, noting all components in satisfactory operating condition.

Responded to noise complaint from HVAC system. Diagnosed issue as loose register dampers causing clanking noise when system is operational. Successfully tightened dampers, resolving the noise problem.

Responded to service call for commercial garage heater not producing heat. Upon inspection, identified cracked heat exchanger with significant corrosion and deterioration around burner ports. Unit was red-tagged as unsafe for operation and requires complete replacement.

Inspected boiler system with reported intermittent zone control issue. Observed Tekmar 260 control panel functioning normally, showing proper temperature readings. Examined zone valves and associated piping; system was operating correctly during service visit with all zones responding properly to thermostat commands. No intervention required as all components were functioning within parameters at time of inspection.

Completed preventative maintenance on Fall PA system including service of 2 in-floor heat boilers, 1 furnace, 1 humidifier, and 1 gas fireplace. All systems inspected and verified operational with appropriate pressure and temperature readings. No issues identified during maintenance.

Diagnosed furnace failure caused by faulty igniter as confirmed with digital clamp meter testing. Removed access panel, replaced defective igniter component, and verified proper ignition sequence and system operation before completing service.

Responded to service call for recurring condensate pump leak. Upon inspection, found damaged condensate pump with broken component on rear section, showing evidence of water damage to surrounding baseboard. Replaced faulty condensate pump to resolve the persistent leakage issue.

Responded to emergency call for overheating boiler system affecting multiple zones. Diagnosed faulty Taco zone control board preventing proper zone closure. Replaced control board and verified proper operation of NTI boiler system with temperature now regulated at 69°F. All zones now functioning correctly with no overheating issues.

Completed routine heating maintenance on customer's system which includes a boiler, HRV, gas fireplace, and Aprilaire 600 Series humidifier. Inspected all components for proper operation and replaced the humidifier filter pad as part of the scheduled service. Customer was not present during visit; left voicemail and text message to reschedule remaining portions of maintenance.

Diagnosed temperature inconsistency in dual-zone system caused by loss of power to zone dampers. Replaced failed Honeywell zone controller module to restore proper functionality to 10-year-old furnace system.

Performed maintenance service on two gas fireplaces, including cleaning and comprehensive tune-ups. For the malfunctioning unit that would light but extinguish after several minutes (while maintaining pilot light), diagnosed structural issues including wall cracking and deterioration near the fireplace. Completed necessary repairs to resolve the intermittent flame issue while ensuring all three units are functioning safely and efficiently.

Performed annual boiler maintenance and tune-up service. Inspected burner assembly and heat exchanger components, confirming proper operation and structural integrity. All connections and wiring were verified to be secure and in good working condition.

Completed prepaid maintenance visit on Triangle Tube boiler system and gas fireplace. System inspection found boiler operating normally with proper temperature settings and pressure levels. Customer reported potential water damage in kitchen after bleeding upstairs radiator; company will follow up regarding possible water line issue.

Inspected ductwork system and identified multiple dampers not functioning properly due to missing control levers. Accessed system via customer-provided ladder, assessed mechanical condition, and found some dampers potentially stripped. Installed new damper control levers to restore proper airflow regulation throughout the ducting system.

Performed routine furnace maintenance including comprehensive system tune-up. Inspected circuit board and electrical connections for proper operation. Serviced Breathclean air purification system (Model #7200, S/N 202103757), replacing UV light bulb and filter as scheduled maintenance requirement.

Performed scheduled Fall tune-up service on Bryant HVAC system, including inspection of furnace and humidifier plumbing. Conducted comprehensive diagnostic testing with Testo analyzer, confirming system is operating within normal parameters. All components verified to be in good working condition with no issues requiring attention.